These days, offline monitoring of dredging equipment can easily be done by acquiring the equipment’s digital data. The data can then be quickly visualised using in2Dredging’s Equipment Performance Review (EPR) and its new Proximity Tool. Regular monitoring by project stakeholders is key for the continued improvement of accurate and efficient operations.

Monitoring Proximity

Monitoring the proximity of a piece of equipment relative to a surface is often critical to a project and accomplishing this can sound abstract and even alarming. Nonetheless, project teams may come across this challenge during subsea operations.

By knowing the distance between a piece of equipment and a surface, the following can for example be determined:

- Overdepth dredging – dredging that occurs below design

- Bench height or cut depth – the depth of excavation below the soil surface

- Standoff distance – distance of a tool froma triangulated surface or subse infrastructure.

- Under keel clearance – the distance between a ship’s hull and the seabed

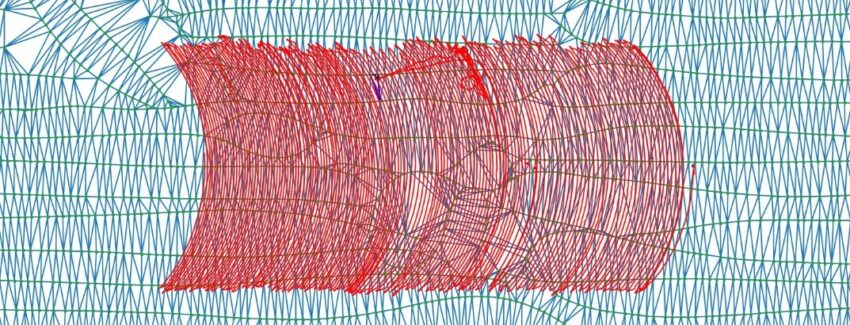

For this reason, in2Dredging (i2D) developed a new feature into EPR called the Proximity Tool. This tool quickly calculates the distance between a point and a surface by using a very fast and advanced triangulation routine. In addition, the tool’s speed helps process long timeseries with a large surface in a fraction of a second, as shown in the figure below.

The Proximity Tool’s Features

EPR’s new Proximity Tool provides many new monitoring capabilities as well as allowing more advanced analyses, such as:

- Identifying, locating and minimising over-dredging

- Safeguarding the standoff distance from subsea infrastructure

- Calculating and increasing the excavation depth of a drag head

- Estimating spill rates accurately, by comparing dredge depth versus seabed level

- Calculating and reducing excavation equipment’s specific energy used, which is made possible thanks to the Proximity Tool’s ability to provide bench height or cut depth

- Ensuring sufficient under keel clearance is maintained at all times

Moreover, the Proximity Tool makes it possible to gain full insight into site operations and allows their continuous improvement with the power of hindsight. Both contractors and owners benefit from having available undisputable evidence.

The new tool makes it possible to further improve:

- Accuracy, efficiency and productivity

- Recording, visualisation and the drawing of conclusions from historical events

- Analysis and development of predictive modelling

- Permit and social compliancy

The opportunities for continuous improvement with the new Proximity Tool are endless. Also, an Equipment Performance Review (EPR) instance can be set up within days to help you gain the necessary insight required to continuously improve your site operations