In order to determine suction and discharge production, successfully characterising soil-mixture viscosity can be key. The latest version of Pumps ‘n Pipeline (PnP), i.e., v1.6.9, can simulate any soil-water mixture in order to estimate production. It can also help users identify and enter the right mixture properties.

Water viscosity is only relevant for medium to coarse granular soils. As for fine granular soils, the carrier fluid can become more viscous due to suspended fine particles. This is known as ‘apparent viscosity’. If the soil-water mixture contains a significant amount of very fine particles in suspension, then the flow behaviour can become non-Newtonian.

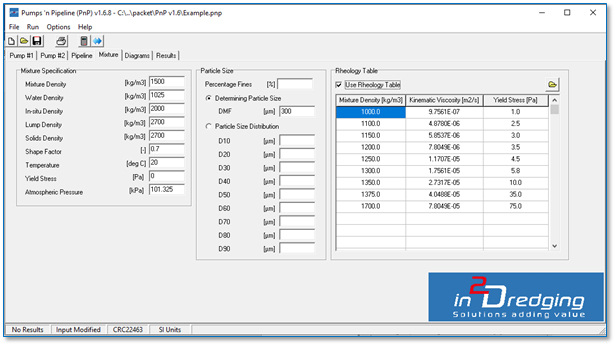

Although viscosity is constant for Newtonian fluids, the viscosity of non-Newtonian fluids varies as a function of the mixture density. For non-Newtonian fluids, yield stress also affects its behaviour. Furthermore, the mixture’s yield stress significantly affects the pipeline’s characteristics. Consequently, yield stress should always be taken into account in order to accurately estimate suction and discharge production. PnP helps users by focusing on the most influential mixture properties, as shown in the figure below.

Water Viscosity

The viscosity of water depends on its temperature, which should be entered into PnP in either Celsius or Fahrenheit. A higher temperature reduces the water’s viscosity, making it easier to flow. However, since this influence is typically small, approximating the temperature is usually enough for an accurate production estimate.

Apparent Viscosity

The fine particles, i.e., of less than 63 micrometres, affect apparent viscosity, a phenomenon discovered by Albert Einstein in 1905. Measuring the soil particle size distribution using a hydrometer can be crucial when significant amounts of fine particles are present.

Apparent viscosity has been included in PnP v1.6.9 to refine production estimates’ accuracy, as requested by users, even though its impact on the production estimate is generally small.

Mixture Viscosity and Yield Stress

For soil with suspended particles of minus 10 micrometres (e.g., clay and mud), the chemical forces become significant, causing non-Newtonian flow behaviour. For a non-Newtonian fluid, the mixture viscosity varies depending on the mixture density. However, the yield stress also needs to be known, and can be measured with a rheometer. These measurements provide a table of mixture density, kinematic viscosity and yield stress. They can be imported into PnP using any table, as well as any comma, tab or space delimited file.

Geotechnical Investigation

Geotechnical site investigations should sufficiently sample and test the soil in order to characterise soil mixture properties. If you are potentially going to be pumping a non-Newtonian fluid, this has to be considered early in a project. Relevant soil parameters need to be determined and measured in order to assess whether the clay or mud is in suspension, and if so, how it will affect suction and discharge production.

We try to share our knowledge proactively with these white papers. However, do you want to learn more? Then read our posts on the Pumps ‘n Pipeline webpage or browse through the PnP User Manual.

If you need to specify a site investigation to ensure all key parameters for dredging are defined, contact in2Dredging.